According to Honeywell’s August 16, 2021 announcement] Honeywell has provided a new type of satellitedrone communication system for Pipistrel’s fixed-wing Surveyor and Nuuva V300/V20 UAV platforms. The system has the advantages of light weight and high performance.

Based on the Small UAV SATCOM system, the UAV platform can realize air-to-ground transmission of real-time video streams with global coverage, supporting functions such as beyond-horizon freight. In addition, based on this system, the small UAV platform can maintain communication connections in remote areas/sea areas that cannot be covered by the ground communication network, and effectively perform related tasks.

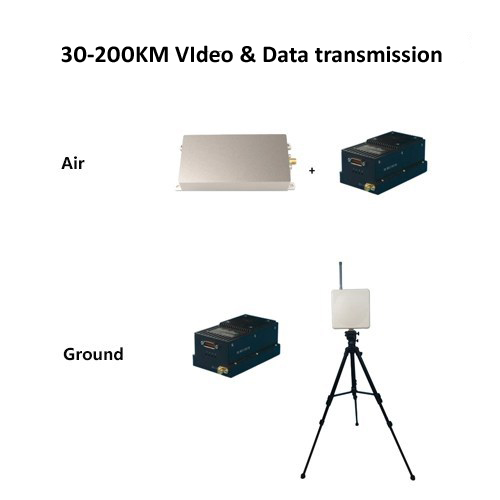

Flydragon long-distance image, data drone communication system , and remote control integrated data link products provide highly reliable communication connections for industrial-grade unmanned systems. has strong anti-interference performance, stable signal, rich interface types, supply30-200KM link custom made.,

The Flydragon-SDI data link has a built-in industrial-grade high-performance H.264 image encoder, supports SDI interface video input, realizes three-in-one image transmission, data transmission, and remote control. The ground end outputs a video stream through a network interface and uses computer software to decode The decoding software has local storage and forwarding functions. The end-to-end image delay is at least 250ms.

Features typical application Figure 2. Typical application of Flydragon-SDI data link

FlyDragon supply 30-200 KM Video & Data drone communication system

100 KM long range Video & Data and telemetry for UAV

Working in L, S band

Broadband transmission, air rate 10Mbps

Communication link establishment/recovery time is less than 10ms

Reliable communication and strong anti-interference ability

Excellent electromagnetic compatibility, no interference to GPS, pod and gimbal

Transmission distances of 3, 5, 10, 20, 40 kilometers and more than 50 kilometers can be selected (under visual conditions)

With 1 1080P60 SDI HD image, 4 digital transmission, 2 remote control interface

1 independent PWM channel output on the airborne end, can be used for signal control such as drop and lighting

The ground side adopts software decoding, and the decoding software has local storage and forwarding functions

Optimized transmission of 1080P high-definition video stream with minimum end-to-end delay of 250ms

Can realize point-to-point, point-to-multipoint, relay networking applications

Cold start time 5 seconds.

When users choose SDI interface pods, they need to choose Flydragon-SDI data link radio. InfoFly-SDI has a built-in high-performance industrial-grade SDI interface encoder that outputs H.264 code stream.

Airborne end: SDI interface connects to pod or PTZ camera; COM1 interface connects to flight control data transmission interface for data transmission between flight control and ground station; SBUS1 interface connects to flight control for manual remote control flight; SBUS2 interface Connect PTZ to control PTZ. If the gimbal supports data transmission port control, InfoFly-SDI has 4 data transmission interfaces, and it can also support the gimbal control through the data transmission port.

Ground end: LAN port connects to the computer, receives H.264 high-definition image code stream and performs software decoding. The decoding software has functions such as local storage and network forwarding. The COM1 port is used to connect the flight control ground station to complete the telemetry remote control data transmission; the COM2 port can be used to control the gimbal and pan/tilt; the PPM1 remote control interface is connected to the first remote control through the trainer line to control the flight; the PPM2 remote control interface is passed The trainer line is connected to a second remote control for controlling pods or other loads. If the PTZ on the airborne end is controlled by a digital transmission interface, the ground needs to connect the PTZ control box to the corresponding digital transmission interface.

Contact: Fly Dragon Drone Tech.

Email: frank at dronefromchina.com

Add: NO. 9 Dayu Road PiDu distric, ChengDu 611730, China